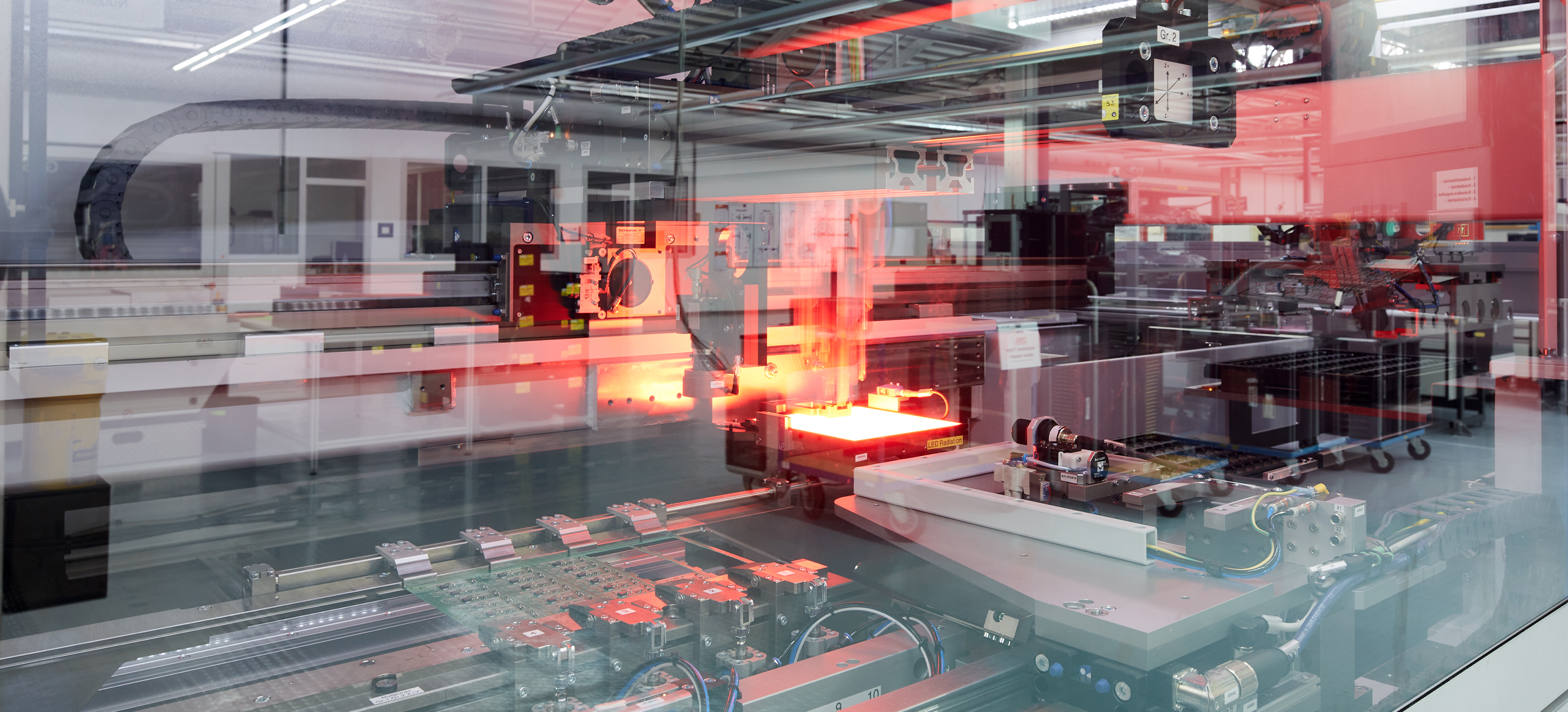

With the establishment of the competence center Dr. Schneider EMS GmbH, we laid an important foundation for the manufacture of electronics at our Kronach site. Since then we have combined our know-how in plastics and electronics production efficiently so that we can give our customers the option of a value-adding process from a single source.

Development times are shortened, manufacturing processes accelerated and interfaces reduced. This enables us both to create innovative, electronic assemblies for the automotive world while also expanding our EMS service for customers from sectors such as industrial applications, transport, consumer electronics, medical technology, smart city, building automation and energy.

Text

Text

Text

Text

Text

Text

Text

Text

Text

As a full-service EMS provider, we handle complete contract manufacturing for electronic and mechatronic assemblies, devices and systems, including development, EMC tests, logistics and after-sales. The latest MES and ERP systems assist us in optimizing production and digitalizing processes.

Total surface area of the production hall

SMD assembly on 3 high-performance lines

pre- and final assembly

cable production

warehouse

administration

Unit quantities with batch sizes

of 500-200.00 units/year

Complexity per assembly

Our collaboration with customers extends from acting as an "extended" workbench through being a full-service supplier all the way to entirely new approaches.

We accompany the development of electronic and mechatronic product and system solutions in a flexible way. By flexible, we mean that our customers decide when to involve us in which product life cycle phase and how deeply they want to collaborate with us. These are our core areas of expertise:

In the production of electronic and mechatronic assemblies, our high quality standards and zero-defect culture enable us to manufacture PCBs quickly and cost-consciously in small, medium or large series. We specialize in automated SMD assembly and manual follow-up processes and have a large pool of machinery for:

We cover the entire logistics chain reliably and with a focus on quality and service. We source globally, cooperating with certified partners with whom we have a long-standing supplier relationship. Our services in detail:

Our assembly covers electronic assemblies, system solutions and devices. We always take the product-specific requirements of our customers into consideration. To ensure cost-effective production, we automate assembly processes as much as possible from the start, integrating individual assembly stations into the production line from the word go. We can also offer manual assembly for miniaturized assemblies as an option. Our services include the following:

We can in principle relocate assembly to our foreign partner plants.

The EMC lab is where comprehensive EMC tests are performed professionally in accordance with basic, technical and product standards. We specialize in EMC measurement, EMC tuning and EMC-compliant development, but we also develop and optimize test and inspection concepts. Our laboratory staff apply the following test procedures:

You can read more about our products and innovations

As world leader for innovative ventilation systems, we make sure you always have the right temperature.

As world leader for innovative ventilation systems, we make sure you always have the right temperature. Our intelligent modular storage systems ensure an impeccably organized interior.

Our intelligent modular storage systems ensure an impeccably organized interior. Our kinematic systems convince with their clear design and an optimum of functionality.

Our kinematic systems convince with their clear design and an optimum of functionality.